ImageIR 8300 hs Key Benefits:

- Ultra‑high frame rates in full frame and sub‑frame modes for capturing fast thermal events

- Exceptional thermal sensitivity for detecting even the smallest temperature differences

- Innovative HOT long‑life detector technology reduces cooler stress and extends operational lifetime

- Wide temperature measurement range capable of handling large gradients in extreme processes

- Modular system design with flexible optics and motorized focus for tailored setups

- Fast rotating filter wheel options for multi‑spectral imaging and enhanced measurement adaptation

- 10 GigE high‑speed interface for loss‑free real‑time data transfer and analysis

- Robust integration and control features, including remote and web‑based operation

Ideal Solution For:

- Dynamic process analysis in manufacturing and research involving rapid thermal changes

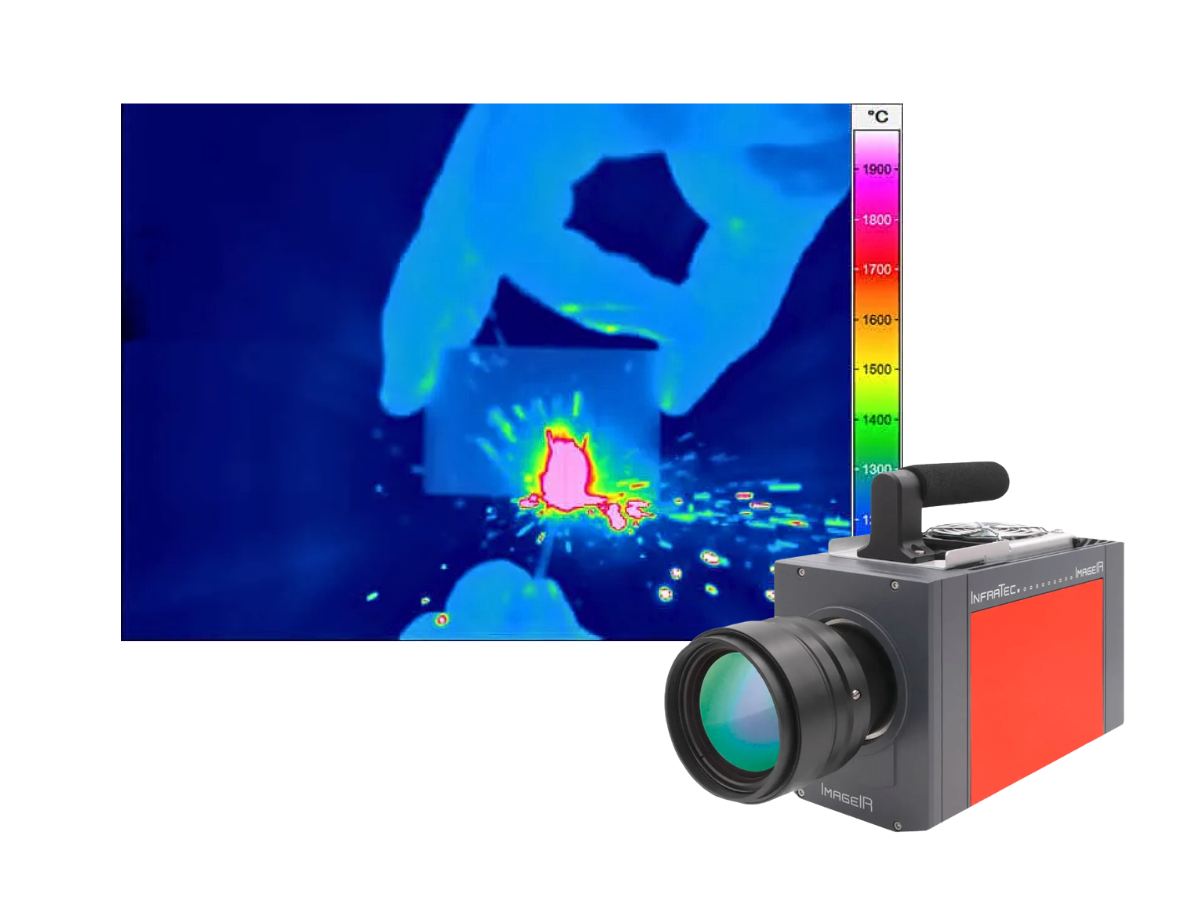

- Explosive event and discharge monitoring where large temperature gradients occur

- Laser machining and welding analysis

- Electrical discharge and failure diagnostics in high‑voltage systems

- Non‑destructive testing (NDT) with high temporal resolution imaging

- Additive manufacturing and rapid thermal process evaluation

- Automotive and aerospace component evaluation under dynamic thermal loads

Technical Specifications

Specification |

ImageIR 8300 hs |

| Spectral Range | InSb: (1.5 - 5.5) µm; T2SLS: (1.5 - 6) µm |

| Pixel Pitch | 25 µm |

| Detector | T2SLS or InSb |

| Detector Format | 640 x 512 pixels |

| Detector Cooling | Stirling Cooled, HOT long-life (T2SLS) |

| Image Recording Principle | Snapshot |

| Readout Mode | IWR |

| Aperture Ratio | F/2.0 |

| Temperature Measurement Range | -40 to 1,700°C, up to 3,000°C |

| Measurement Accuracy | +/-1°C or +/-1% |

| Temperature Resolution at 30°C | Better than 0.02 K |

| Frame Rate (Full/Half/Quarter/Sub) | Up to 1,105 / 1,957 / 3,731 / 30,330 Hz |

| Window Mode | Yes |

| Focus | Manually, motorized or automatic |

| Dynamic Range | 14 bit |

| Integration Time | 0.5 - 20,000 µs |

| Rotating Aperture & Filter Wheel | Up to 7 positions each |

| Interfaces | 10 GigE, HDMI |

| Protection level | IP54 |

| Dimensions, Weight | 235 x 120 x 160 mm; 4 kg |