ImageIR 5300 Key Benefits:

- Ultra-fast snapshot detector capturing high-speed thermal events with minimal blur and rapid integration times

- Up to 481 Hz full-frame and up to 105,000 Hz in sub-frame mode for analyzing dynamic processes

- High thermal sensitivity (0.015 K) for detecting the smallest temperature differences

- Motorized filter wheel enabling spectral thermography with up to four specialized filters

- Precise thermographic measurement with calibrated curves and ±1 °C or ±1 % accuracy

- Modular design and robust housing for flexible configuration and reliable operation in industrial environments

- Trigger interfaces and GigE Vision compatibility for synchronized acquisition and easy integration into automated systems

Ideal Solution For:

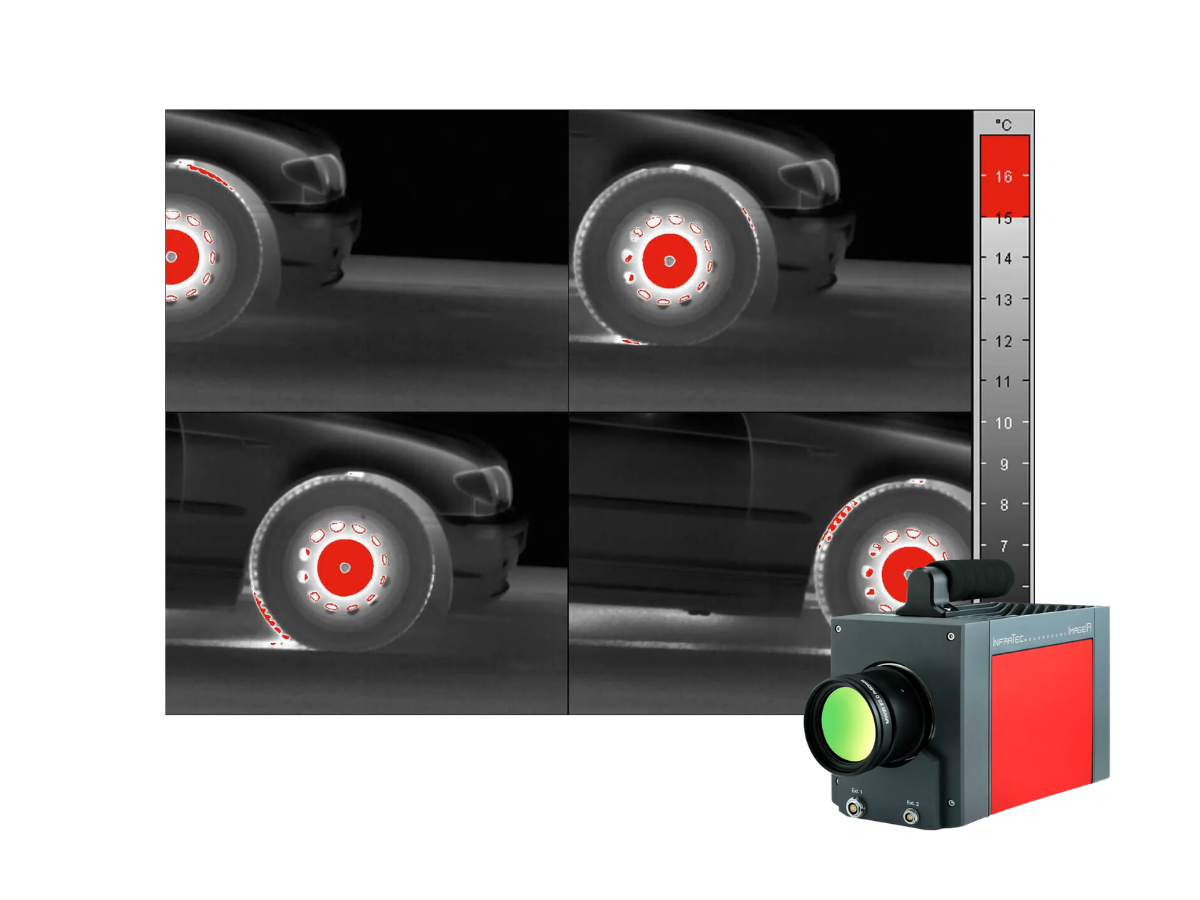

- High-speed thermography and transient thermal analysis in research and development

- Spectral thermography for material-specific measurement tasks with customized spectral filtering

- Fast process monitoring such as combustion analysis and rapid thermal transitions

- Non-destructive testing (NDT) of components and assemblies

- Industrial quality assurance and process control requiring high frame rates and precise thermal profiling

- Automated test systems and inline inspection for aerospace, automotive, and manufacturing

- Scientific investigation and flow/thermal dynamics research where microsecond-level timing is critical

Technical Specifications

Specification |

ImageIR 9400 hp |

| Spectral Range | 3.7 - 4.8 µm |

| Pixel Pitch | 30 µm |

| Detector | MCT |

| Detector Format | 320 x 256 pixels |

| Detector Cooling | Stirling Cooled |

| Image Recording Principle | Snapshot |

| Readout Mode | ITR |

| Aperture Ratio | F/2.0 |

| Temperature Measurement Range | -40 to 1,200°C, up to 3,000°C |

| Measurement Accuracy | +/-1°C or +/-1% |

| Temperature Resolution at 30°C | Up to 0.015 K |

| Frame Rate (Full/Half/Quarter/Sub) | Up to 481 / 1,906 / 7,229 / 105,000 Hz |

| Window Mode | Yes |

| Focus | Manually, motorized or automatic |

| Dynamic Range | Up to 16 bit |

| Integration Time | 1 - 20,000 µs |

| Rotating Aperture/Filter Wheel | Up to 5 positions |

| Interfaces | GigE, HDMI |

| Protection level | IP54 |

| Dimensions, Weight | 241 x 120 x 160 mm; 3.3 kg (without lens) |